MCIM9070 2 Zviteshi zveThermoformer

Machine Details

Usage

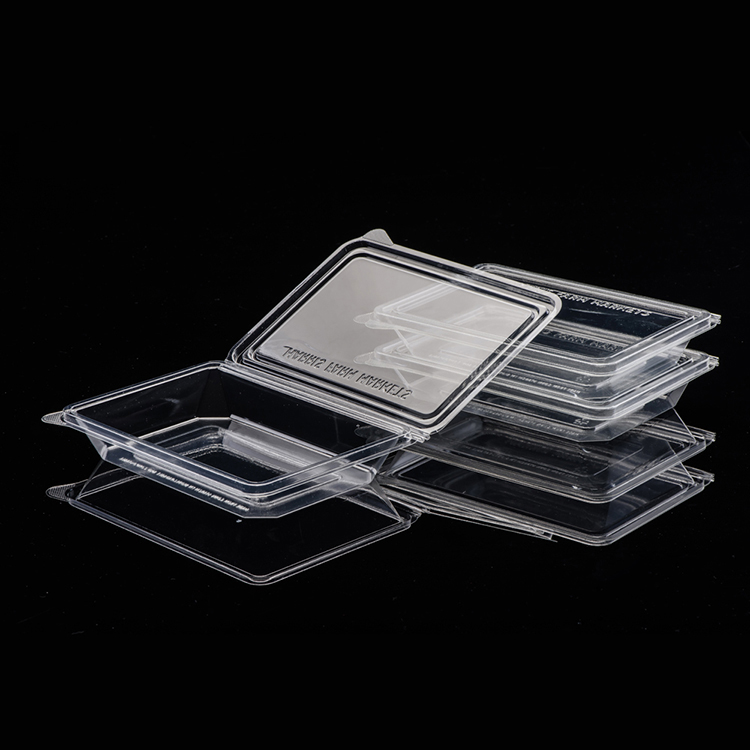

Muchina uyu wakagadzirirwa kugadzira ese saizi yekurongedza midziyo, yakavhurika-mhando ine madziro akatetepa, nekushandisa roll-sheet, pasi pepamusoro-kumhanya vacuum suction-forming process.Zvigadzirwa zvakagadzirwa nemuchina uyu zvinogona kushandiswa pasuru yezvikafu, vashanyi-zvinhu, machira, zvekurapa, toyi, zvizorwa, zvinhu zvemagetsi uye zuva nezuva rinoshandiswa zvakaoma-ware, nezvimwe.

Suitable Sheet

Starch-dhipoziti mapepa, mwenje-dhipoziti pepa, nharaunda pepa, APET, PETG.PVC, HIPS, PET, PS, OPS, nezvimwewo.

Mamiriro ezvinhu

Mechanical, pneumatic uye magetsi musanganiswa, ese zviito zvekushanda zvinodzorwa nePLC.Bata skrini inoita kuti kushanda kuve nyore uye nyore.

Kugadzira mhando: kumanikidza uye vacuum kugadzira

Up/down mold forming type.

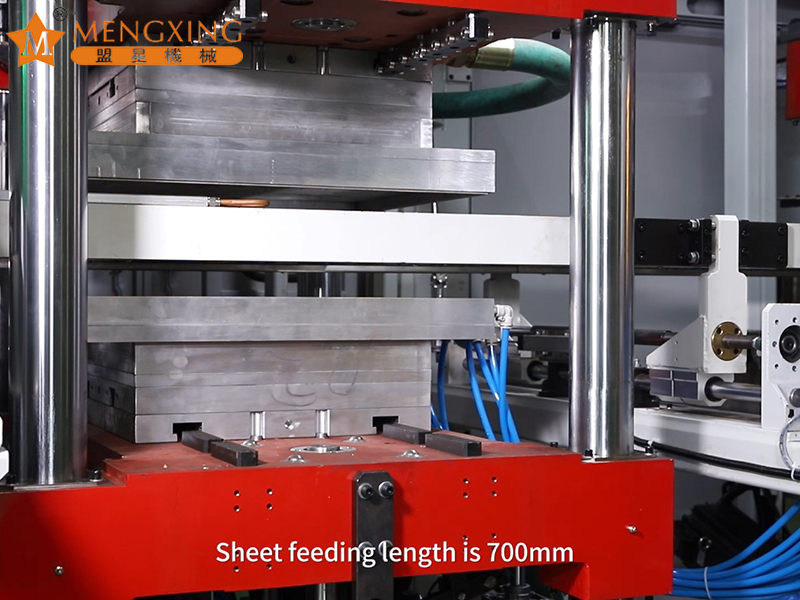

Servo mota yekudyisa, kureba kwekudyisa kunogona kugadziridzwa nhanho-shoma.High kumhanya uye yakarurama.

Kumusoro hita ine zvikamu zvitatu zvekudziya, pasi hita ine zvikamu zvitatu zvekudziya.Ne sheet edge preheating.

Ne sheet edge preheating.Dzivisa bepa rakatyoka.

Heater ane njere tembiricha kudzora hurongwa, otomatiki kupa kudziyisa munhu hita kudzora.Kupisa nekukurumidza (3 maminetsi kubva pa0-400 dhigirii), haizoitwe nemagetsi ekunze

Kugadzira uye kucheka chiteshi chakavhurika / kuvhara mold inodzorwa ne servo mota, yakakwirira yekucheka chaiyo.zvigadzirwa otomatiki accounting kubuda.

Kuturikidzana mhando: pasi pasi stacking / manipulator stacking.

Iine ruzivo rwezvigadzirwa uye inomhanyisa data nemusoro basa.

Nekukurumidza kuchinja mold system, , inoshanda zvakanyanya.

Kudyisa hupamhi inogona synchronously kana yakazvimirira kugadziriswa nenzira yemagetsi.

Heater otomatiki inosundidzira kunze kana shiti ratopisa.

Auto roll sheet kurodha, kuderedza basa rekushanda.

Technical Parameter

| Kufara kweshiti (mm) | 590-940 | |

| Ukobvu hweshizha (mm) | 0.1-1.5 | |

| Hukuru hweshizha dhayamita (mm) | 800 | |

| Kugadzira mold stroke (mm) | Kwirai mold 170,Pasi mold 170 | |

| Kukiya mold force (ton) | 80 | |

| Nzvimbo yakakura yekugadzira (mm2) | 900×700 | |

| Min kugadzira nzvimbo (mm2) | 550×400 | |

| Kugadzira mold wide (mm) | 550-900 | |

| Kugadzira urefu hweforoma(mm) | 400-700 | |

| Kuwedzera kuumba kudzika/kureba (mm) | Manipulator :90 /80;Pasi stacking:155/155 | |

| Kucheka simba (ton) | 90 | |

| Stacking nzira | Kudzika pasi / Manipulator stacking | |

| Nguva yekutenderera (kutenderera/ min) | Manipulator: Max20; Kudzika pasi:Max40 | |

| Inotonhorera Outlet | Kutonhora kwemvura | |

| Mhepo inopa | Inzwi (m3/ min) | ≥5 |

| Pressure (MPa) | 0.8 | |

| Pombi yevacuum | Busch R5 0100 | |

| Magetsi | 3 chikamu 4 mitsetse 380V50Hz | |

| Simba reheater (kw) | 145 | |

| General simba (kw) | 190 | |

| Dimension (L×W×H) (mm) | 11040×3360×3100 | |

| Huremu ( tani ) | ≈15 | |

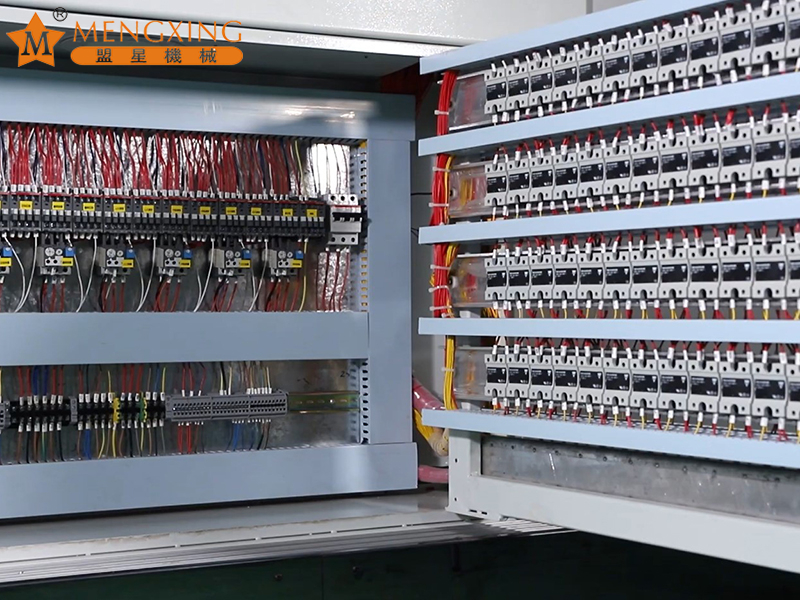

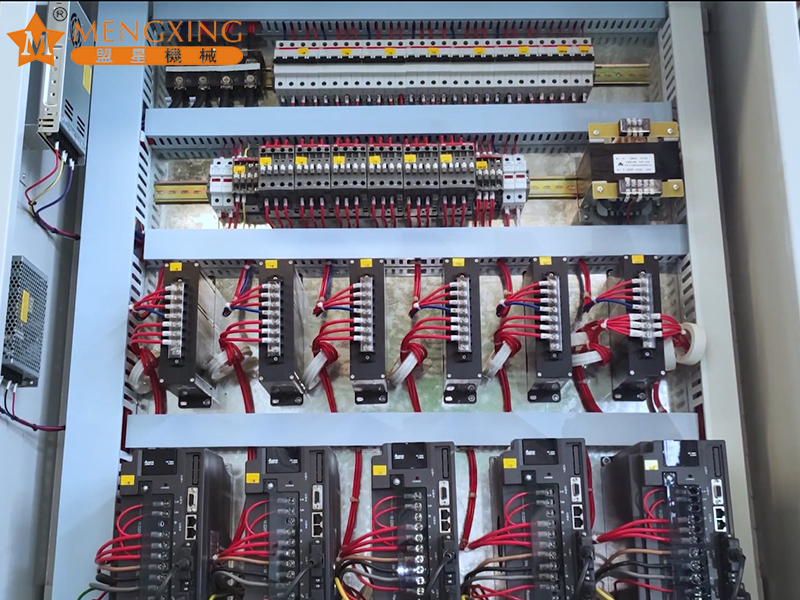

Technical Configuration

| PLC | Taiwan Delta |

| Bata Screen Monitor ( 15 ″ inch / Ruvara) | Taiwan Delta |

| Kudyisa servo mota (5.5kw) | Taiwan Delta |

| Kugadzira kumusoro / pasi servo mota (7.5kw) | Taiwan Delta |

| Plug Batsira servo mota (7.5KW) | Taiwan Delta |

| Heater (288pcs) | Germany Elstein |

| Contactor | Switzerland ABB |

| Thermo Relay | Switzerland ABB |

| Relay | Germany Weidmuller |

| SSR | Switzerland Carlo Gavazzi |

| Vacuum Pombi | Germany Busch |

| Pneumatic | JAPAN SMC |

| Cylinder | JAPAN SMC & Taiwan Airtac |

Sei kusarudza isu

Chigadzirwa chehunyanzvi, zviratidzo zvehupfumi zvasvika pachiyero chenyika, chinofananidzwa nerudzi rwekune dzimwe nyika, muna 2006 kuburikidza ne ISO9001: 2000 quality management system certification, chigadzirwa chinotengeswa zvakanyanya mumisika yemumba neyekunze, inovimbwa zvakanyanya nevashandisi.

Muenzaniso Mifananidzo

Container Mifananidzo