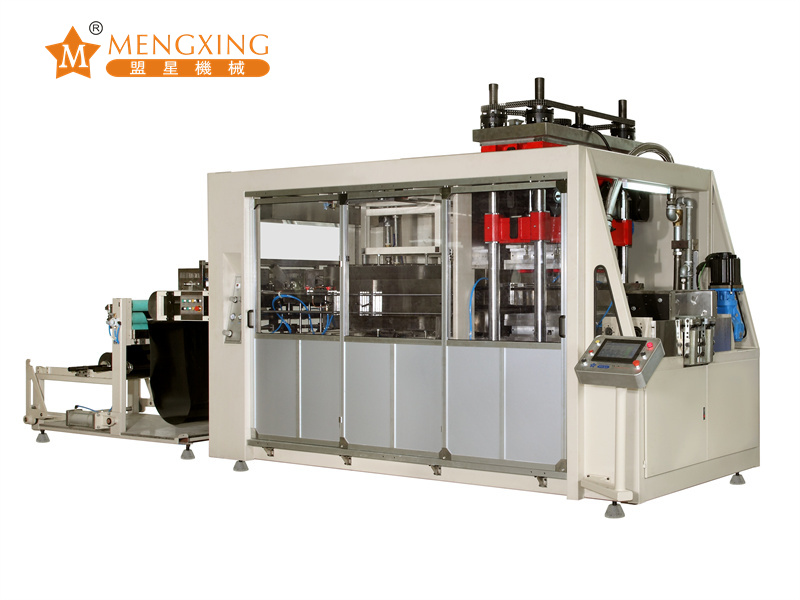

QZC50-80/120-CWF Thermoformer

Machine Details

Ini, Feature

01. Mechanical, pneumatic uye magetsi kusanganiswa.Zvese zviito zvekushanda zvinodzorwa nePLC ine touch screen, iri nyore uye nyore mukushanda.

02. Servo mota yekudyisa, kureba kwekudya kunogadziriswa zvisina nhanho, inokurumidza uye yakarurama.(Max.speed:1000mm/s)

03. Heater ine intellectual tembiricha yekudzora system inogona kupa otomatiki iyo yekudziya yega heater control, iri nyore kune tembiricha yakafanana. Iyi sisitimu ine zvakanakira kushanda kuri nyore, zviri nyore, kupisa nekukurumidza (chete 5 min kubva pa0-400degree), yakagadzikana (yakakunda' t inoitwa nemagetsi ekunze, kutsika kwekushisa kuri pasi pe1 degree), kuchengetedza simba (anenge 15%) uye hupenyu hurefu hwekushandiswa kwemoto.

04. ]Double hita(kumusoro uye pasi) ine sheet pro-heat midziyo.

05. Nemashizha akadonhedza kuona uye kudzivirira midziyo.

06. Feeing sheet mberi kwenguva.Muchina uyu une otomatiki ndangariro basa rekudziya nguva kuita kuti muchina uwane yakajairika kushanda mamiriro pakutanga.

07. Mold kunonoka.

08. Iyo yekuumba kumusoro uye pasi mold inoshandisa pneumatic double elbow system uye bhurashi rinotungamira rinoshandisa inlay bearing ine yakasimba lubricant (JFB) kuita kuti kumusoro uye pasi mold ishande zvakatsiga uye nemazvo.Iyo mold clamping force yakakura uye yakanaka pakuvandudza kunaka kwezvigadzirwa.

09. Heater automatic push-out function inoita kuti zvibvire kuchenesa uye pamushini pasina kucheka pepa panguva yekugadzira, wozochengeta pepa.

10 .Iyo kumusoro uye pasi molds inoshandisa magetsi ekugadzirisa system, inomhanya zvakanyanya uye yakanakira.

11. Nekukurumidza kuchinja mold midziyo, pneumatically clamping.

12. Iyo kumusoro mold inoshongedzera mubatsiri anotambanudzira mhepo silinda uye pasi mold inoshongedzera mubatsiri wedemoulding air silinda.

13. Kuumba kune mhando dzakawanda dzinofanira kusarudzwa---vacuum forming, pressure forming, vacuum uye pressure form.

14. Otomatiki roll sheet kurodha, kurerutsa simba rekushanda.

II,Technical Parameter

| Parameter | QZC50-80/120-CWF (modhi Nha.) | |

| Pepa Riri kuwanikwa(mm) | 500-760 | |

| Ukobvu hweshizha(mm) | 0.3-1.5 | |

| Max.dia.yepepa roll (mm) | 600 | |

| Up mold stroke(mm) | 130 | |

| Down mold stroke(mm) | 130 | |

| Max.forming nzvimbo(mm2) | 720×750 | |

| Max.forming urefu(mm) | 70 | |

| Max.kuumba kudzika(mm) | 100 | |

| Kugona (Cycle/min) | 6-16 | |

| Kunobva Gasi | Mhepo inopa (m3/min) | ≥3 |

| Pressure(MPa) | 0.8 | |

| Kushandiswa kwemvura | 4-5 Cube / Awa | |

| Pombi yevacuum | Busch R5 0100 | |

| Simba | 380V/220V 50Hz | |

| Simba reheater (Kw) | 86.4 | |

| Motokari magetsi (Kw) | 8 | |

| General simba (Kw) | 96 | |

| Dimension (L×W×H)(mm) | Nezve 7500×1800×2300 | |

| Huremu (Kgs) | Vanenge 7800 | |

III,Technical Equipment

| PLC | Taiwan Delta |

| Bata skrini yekutarisa ( 10.4 ″ inch / Ruvara) | Taiwan Delta |

| Kudyisa mota (4.5kw) | Taiwan Delta |

| Heater | Jerimani |

| Solid voltage regulator | China |

| Contactor | Germany Siemens |

| Thermo relay | Germany Siemens |

| Relay | Germany Weidmuller |

| Pombi yevacuum | Busch R5 0100 |

| Pneumatic | Japan SMC |

| Cylinder | China |

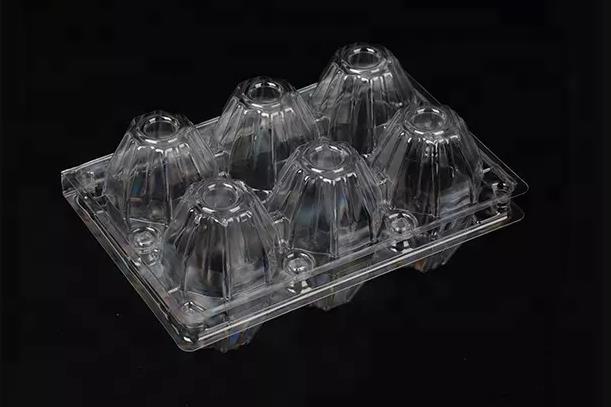

Muenzaniso Mifananidzo

Container Mifananidzo